HeroSecondaryQuote

JSS component is missing React implementation. See the developer console for more information.

The term “digital twin” has become increasingly popular in the business world, particularly in relation to process mining. But it isn’t a new concept. It's rooted in high-tech engineering, where it’s been instrumental in driving data-led innovation for decades.

Simulation, like digital twins, is a valuable analysis tool. Both are useful in industries like manufacturing and engineering, where prototyping and testing is prohibitively expensive, and error margins are minimal. They allow you to design, simulate, and refine systems in the digital realm before you construct their real-world counterparts. So, what’s the difference between digital twins and simulation?

A digital twin is a virtual replica of a physical entity, continuously updated with live data to mirror its real-world counterpart. In contrast, simulation involves using predefined data to model scenarios and analyze potential outcomes in a controlled environment. Together, they empower businesses to optimize their processes, reduce costs, and mitigate risks effectively.

In this article, we’ll delve into digital twins and simulations, discuss their purpose and differing scope, and most importantly, the benefits of using them together.

Jump to:

What is a digital twin?

What is simulation?

What’s the difference between digital twins and simulation?

How digital twin and simulation work together

Benefits of combining digital twins and simulation

What is a digital twin?

A digital twin is a virtual model of a physical object or system. It works by creating a digital representation of the object and mirroring its real-time behavior, performance, and features.

To create a digital twin, the physical object—for example, a medical device or jet engine—is fitted with smart sensors to collect data on its behavior and functionality. The system will process and actively apply this information to the virtual model.

The main purpose of a digital twin is to remotely monitor an object’s performance, enabling you to identify potential problems and make informed decisions to improve the original physical asset.

What is simulation?

Process simulation, also known as simulation, is a model of a system or scenario used to run experiments and study future outcomes.

Simulations are typically digital models that use computer-aided design (CAD) or computer-aided engineering (CAE) software applications. CAD creates detailed 2D or 3D models of a product or process, which the simulation then uses to test variables and analyze the performance of designs under various conditions. You can also create simulations using mathematical modeling.

Simulations play a vital role in process intelligence, allowing businesses to test changes before implementing them to optimize processes.

What is the difference between digital twins and simulation?

A digital twin is a virtual replica of a physical object or system that’s powered by real-time data. Digital twins provide full visibility of an asset’s performance thanks to their continuous feed of performance data, offering accurate predictive analysis. On the other hand, simulation is a virtual model of a product or process used for experimental analysis. Designers can use a simulation to introduce or test specific scenarios and get theoretical performance data.

Some of the key differences between digital twins and simulation, in detail, are:

Scope

- Digital twins provide a dynamic view of an object or process throughout its lifecycle. They create a real-time, digital replica of a physical object or system by continuously integrating data gathered by sensors and other sources to reflect an asset’s current state and performance. Digital twins offer more than just operational insights. By providing a constantly updated feed of process data, historical information, and future projections, a digital twin is a comprehensive lifecycle management tool.

- Simulation uses predefined data sets to perform experiments or run possible scenarios. Simulations provide a mechanism to study system behavior and performance in a controlled, virtual environment, and don’t typically use real-time data. The scope of simulation is generally fixed to the duration and objectives of each specific experiment. It provides insights for planning, decision-making, and problem-solving within a defined context.

Data integration

- Digital twins are active virtual models that use and deploy real-time data for continuous updates. This two-way data flow creates a dynamic and accurate model that reflects the current state of its physical counterparts. Digital twins are an optimal choice for continuous monitoring, diagnostics, and optimization.

- Simulations are static digital models that use predefined data sets and do not typically incorporate real-time updates. These models remain unchanged unless a designer manually introduces new elements or parameters. While a simulation is great for experimental analysis, its lack of real-world data restricts it from delivering ongoing insights.

Purpose and usage

- Digital twins are most useful for supporting asset and process management, as well as conducting predictive maintenance. The digital model emulates what’s actually happening to a product. With this level of visibility, you can monitor asset performance over its full lifecycle to minimize downtime, avoid unexpected process breakdowns, and make proactive decisions.

- Simulations, on the other hand, are more beneficial for assessing product design, training, education, and strategic planning. CAD-based simulations enable designers to test a virtual model against a list of potential scenarios within specific parameters. Designers can use this data to evaluate potential process outcomes as well as develop strategies in a controlled, risk-free environment.

Interactivity

- Digital twins allow for dynamic interaction with the model, so you can test different scenarios with real-time feedback. Live data integration is a standout feature of digital twins that enables them to evolve and adapt over time. They continuously provide insights as more data is collected and analyzed throughout the product lifecycle.

- Simulations require designers to set variables and parameters, before running the model, to observe outcomes. They don’t typically incorporate real-time data, resulting in a more static model that requires manual updates. This makes simulation an ideal tool for running replicable scenario tests where continuous or adaptive insights are less critical.

Digital twins vs. simulation

| Digital twins | Simulation | |

| Scope | Comprehensive and dynamic business-wide insights | Focused predictive insights |

| Data integration | Continuous, two-way data flow with real-time feedback | One-directional data flow, based on predefined parameters |

| Purpose | Real-world monitoring, analysis, and process optimization | Experimental analysis and scenario planning |

| Usage | Asset management, predictive maintenance, and proactive decision-making | Training and education, risk management, and strategic planning |

How digital twins and simulation work together

Using digital twins and simulations together significantly enhances business processes by combining real-time, detailed representations of physical entities with the predictive power of experimental analysis.

Digital twins provide current asset performance data that can be used to facilitate more dynamic simulations. This integration provides enhanced insights for more accurate scenario testing, leading to better decision-making, operational efficiency, and adaptability.

Here are some industry examples demonstrating the combined power of digital twins and simulation:

Healthcare

In a hospital aiming to optimize patient flow through its emergency department, digital twins can provide a real-time, virtual model of the current patient journey. By integrating simulation, the hospital can test scenarios, such as allocating more staff during peak times. This combined approach will help you ensure proposed solutions don’t inadvertently increase patient waiting times or overburden staff.

Manufacturing

A car manufacturer aiming to enhance assembly line efficiency can use digital twins to create a replica of its current production process. Coupling this with simulation, it can test changes like reordering assembly stations or introducing robotic arms. Employing both tools allows you to anticipate impacts on production, product quality, and worker safety, ensuring any changes align with the desired results.

Banking

To speed up the loan approval process, a bank can create a digital twin of its current workflow. By simulating changes such as automating credit checks or introducing digital documents, the bank can forecast results and reduce risks to optimize processes without compromising the integrity of KYC compliance.

E-commerce

An online retailer aiming to optimize its product return process can use digital twins to model and monitor its existing system in real time. Simulating changes, like simplifying return labels or offering pick-up services, they can assess and prevent any negative impact on operational costs, inventory management, and customer loyalty.

Benefits of combining digital twins and simulation

Digital twins offer businesses an unparalleled view into their operations, but simulations unlock their transformative potential.

By test driving changes in a virtual environment, businesses can innovate faster, reduce risks, and ensure cost effectiveness. Independent of the industry, the power of simulation for realizing the full potential of digital twins is reshaping the way industries approach process optimization.

Cost effectiveness

Introducing a new or updated business process before testing it is expensive and risky, much like prototyping a new airplane solely on theory. By using digital twins in conjunction with simulation, businesses can model planned processes and stress-test their performance under various conditions. This approach prevents resource wastage and minimizes reworks.

Risk reduction

In industries like aerospace, a failed engine prototype could mean significant financial losses and safety hazards. Similarly, in high-risk, heavily regulated fields, such as healthcare and finance, flawed processes can have even more severe consequences. Leveraging digital twins alongside simulation enables organizations to uncover and address potential failures, reducing human and compliance risks.

Speed of innovation

Digital twins have accelerated innovations in engineering for decades by removing the time-consuming physical prototyping phase, and they’ve demonstrated similar benefits across other industries. Similarly, in business processes, simulation fast-tracks changes by instantly showcasing potential outcomes, cutting down lengthy trial-and-error cycles and allowing teams to focus on the most optimal process implementations.

How digital twins and simulation are used for process optimization

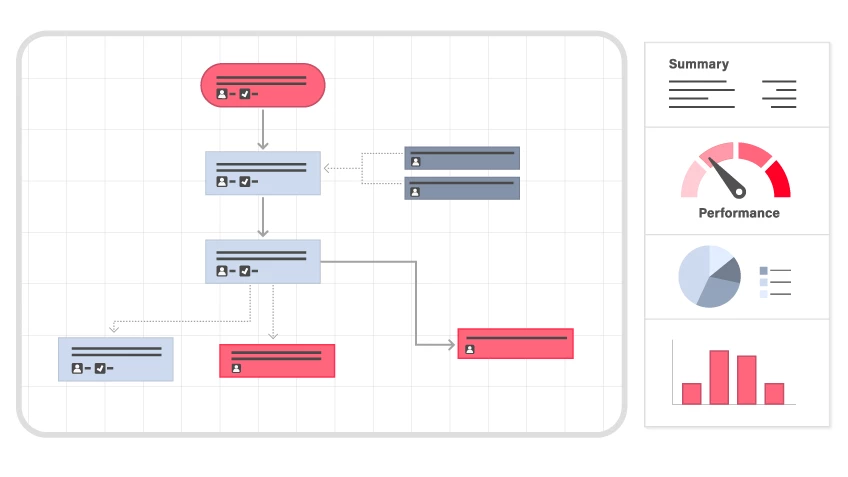

Process simulation is a powerful tool that enables you to use process histories to predict optimization outcomes, without disrupting real operations. With ABBYY Timeline, you can bring those simulations to life with a digital twin, a real-time virtual replica of your process. Our market-leading, all-in-one process intelligence platform gives you a risk-free environment where you can automatically configure an adjustable digital twin to reflect any proposed process changes.

Traditional process mining solutions have long promised simulation capabilities. But modern solutions like Timeline are developed to deliver on all five key pillars of process intelligence, straight out of the box: process discovery, process analysis, process monitoring, process prediction, and, importantly, process simulation.

Simulation is an indispensable final step to translate the process mining process into actionable workflow improvements. Our low-code, user-friendly platform is designed to give you easy access to advanced simulation functionality, so you can test process outcomes before implementation at a low cost and lower risk.

Tell us about a project you think would benefit from digital twin or simulation insights. Fill out the form and select “Process Intelligence”. We look forward to guiding you on your intelligent automation journey.

Subscribe for blog updates

RelevantBlogPosts

JSS component is missing React implementation. See the developer console for more information.

ConnectWithUs

JSS component is missing React implementation. See the developer console for more information.